M1 Rifle Gas Cylinder Lock Screws ©

Like the Gas Cylinder Lock, the Gas Cylinder Lock Screw has evolved through many design changes, until it became the vented, poppet style we know today. The lock screw holds the Gas Cylinder and Gas Cylinder Lock into a steady assembly, which ports gas down through the Gas Cylinder to the operating rod. This porting of gases makes the M1 Rifle an autoloader. The lock screws are listed in chronological order with a brief description to help in their identification:

| Ordnance Part # B147428 | Solid, un-vented screw, identified by one slot which consists of a circular hole centered on that slot. |

| Ordnance Part #B147851* | First vented lock screw, identified by no markings. Stays open even after M7 launcher is removed. The first model provided to the grenadier. Valve lock consists of a carbon steel friction spring. |

| Ordnance Part #B147851* | Second vented lock screw, identified by an S marking. Stays open even after M7 launcher is removed. The second model provided to the grenadier. Valve lock consists of a stainless steel friction spring. |

| Ordnance Part #7310079 | Final WWII design of vented lock screw. This version closes after removal of the M7 launcher, allowing semi automatic fire. There are a variety of markings, indicating the manufacturers' marks. All have a P for poppet style. This is accomplished by an internal helical spring automatically closing the valve when launcher is removed. |

| Ordnance Part #7267797 | Final design, post 1959 production. Eliminated the "P" marking. All production has "T" marking with letter code for manufacturer. |

When reading the above information, it must be remembered that the M7 Grenade Launcher (GL) of WWII had a long stud. This stud acted as the mounting mechanism for the launcher and it depressed the lock screw’s valve, venting gases to the atmosphere. This venting was necessary to prevent high bolt speed during reward travel, which, if not eliminated, would damage the receiver.

Thus, as long as the M7 was attached to the rifle, semi automatic fire was not possible. It wasn’t until the launcher was removed from the rifle, that the gas system could be closed again, and semi automatic fire restored. The result of this very bad feature of the M7 resulted in large quantities of lost Grenade Launchers during combat.

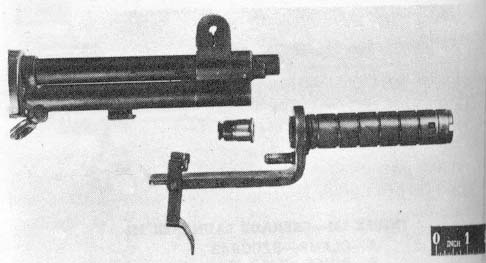

Early model M7 Grenade Launcher showing early vented lock screw with non returning spring and beveled lock.

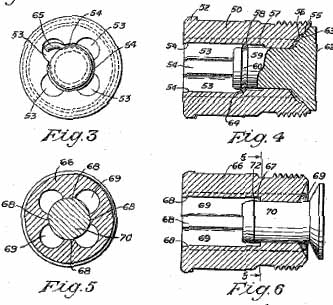

Remington's early drawing of the vented lock screw which would eventually evolve into the version we know of today. Remington engineers Rutherford and Luster designed the lock screw which accompanied Remington's T14 Grenade Launcher during its trials.

A Brief history of each lock screw:

B147428 - The solid lock screw first shows up during the transition from the gas trap Garand to the gas port version. The time period is approximately the fall of 1940 when these rifles start to be altered and produced. The illustration shows a reproduction along side an original. Originals can be difficult to obtain because combination tools always destroyed the slot. Many were junked due to the inability to remove them from rifles as the slots wore out of shape. CAUTION should be taken when purchasing a reproduction. Some of the REPRO manufacturers made the middle circle with a diameter large enough to fit the M5 series bayonet. The thought was that a lock screw that would not accompany the attachment of the bayonet would never sell. Who ever thought of that failed to realize that whatever will accommodate a bayonet will also accommodate the attachment of a grenade launcher. DISASTER WILL HAPPEN IF ANYTHING IS LAUNCHED OFF AN M1 WITH A SOLID LOCK SCREW ATTACHED. Severe injuries to the shooter and major damage to the rifle can result. Make sure you are aware of what you are purchasing. Remember also that one day your rifle will be sold to somebody else who may not have the same knowledge. Original solid lock screws will not accommodate the installation of the M7 Grenade Launcher. The inability to mount the M7 with a non vented lock screw was one of the design requirements as Remington's T14 Grenade Launcher and vented lock screw evolved into the M7 GL and Lock Screw B147851.

Original screw on left, B147428, reproduction on right from mid 1980's. The reduced diameter of the center hole will not allow mounting of a GL. This vintage reproduction has the large center hole which will accommodate both the M5 series bayonets, and unfortunately GL's. Lately many of the reproductions closely resemble originals.

B147851 with carbon steel spring - The first vented lock screw to be used on the M1 had a carbon steel friction spring retaining the valve. This screw and its later version had some very bad design flaws. There was no internal valve closing spring, so when the launcher was removed, the valve stayed opened. This allowed dirt and other foreign objects down into the gas cylinder creating malfunctions. The grenadier had lots of incentive to remove the M7 launcher during WW II, as the long stud always kept the gas system opened, which prevented semi automatic fire.

The carbon steel spring was also highly susceptible to rust, which gave these screws a very high failure rate. During this time period corrosive primed ammunition was all that was available in this caliber, so carbon steel springs had a very short life. Like its later developed replacement, this screw often failed due to M7 launcher's recoil breaking the friction spring. The result was a valve lost, deep into the interior of the gas cylinder, necessitating a complete breakdown of at least the gas system, maybe the whole rifle. Not a happy job in a combat situation! Another major problem with this design was the requirement to fire a round of ammunition to close the valve after removal of launcher. Firing this first round provided the gas to close the valve, which made further semi-auto fire possible. These lock screws are VERY SCARCE on today’s market. They never were plentiful, even 25 years ago. Just remember they are totally unmarked and they stay open. This screw was first produced in quantity upon adoption of the M7 grenade launcher, which puts its standardization in March 1943.

B147851 with stainless steel spring - This screw had all the problems of its predecessor with the exception of the carbon steel spring. The screw lasted longer due to it ability to withstand weather conditions and corrosive primers. It was accomplished by providing the lock screw with a stainless steel friction spring, and was marked with an S to distinguish it from the earlier version. I have a small quantity of these lock screws and they are divided into three categories.

- There are Springfield Armory produced screws that have the "S" rolled on. These have that wartime “pewter” finish, almost bright but not quite. These screws are also VERY SCARCE on today’s market.

- Possibly Springfield Armory produced screws with a hand struck "S". These lock screws are a dull black. It is my belief that the hand struck screws may have been initially the carbon steel type and converted with the changing of the friction spring. These are VERY SCARCE on today's market.

- Contracted lock screws, dull black. The "S" markings are difficult to read, but with magnification can been seen.

I don’t have a date of change to the stainless steel friction spring, but based the very small number of carbon steel type that have survived over the years, my guess is this change occurred very soon after production started, probably within a matter of a few months. Thanks to Scott Duff, we have learned that Springfield Armory produced approximately 36,000 of the stainless version in Fiscal Year 1944**. The contractors that produced the M7 GL's had the responsibility to contract for the lock screws. One screw was packed with each GL coming off the production line.

Left is the SA “pewter finish” B147851, "S" marked lock screw with valve in opened position. Shown alongside it is the friction spring which locks the valve into the screw. Right is the same screw with a blackened finish.

Both of the type #B147851 screws are pretty fragile to handle. The valves can come out easily if forced open with an object. I recommend if you have either one of these lock screws, never try to open the valve by hand. If you push too hard it may come out. It is better opened when installed on a rifle and an M7 launcher is used to open it. With normal handling the launcher’s stud is not long enough to pop out the valve. Both versions of this screw were packed with the M7 grenade launcher. It was the grenadier’s responsibility to replace the solid screw.

7310079 Poppet Style – This final WWII design eliminated all the problems with the non- closing lock screws mentioned above. Standardize in January of 1944 it has been in service all over the world with the M1 rifle. Like any vented lock screw, with repeated use, eventually the valve will wear and leak gas. This leakage can drive somebody nuts when trying to diagnose a short stoke symptom. The lock screw is usually the last place an inexperience person will inspect.

7267797 Poppet Style- This design came into existence in 1959. It eliminated the "P" marking. Has "T" marking. Some claim the internal dimensions are different than the WWII design. Without seeing both drawings, I cannot confirm that, and in my mind it remains open.

Evolution starting from the left. Unmarked carbon steel friction spring, SA Pewter finish with "S" marking, hand struck with "S" marking, WWII poppet style with "P" marking.

To find WWII Non Vented lock screws, click here

*Thanks for Billy Pyle, author of Ordnance Tools, Accessories, & Appendages of the M1 Rifle for his identification of the drawing numbers for the early vented lock screws.

**Thanks to Scott Duff for his finding the production figures on Springfield Armory’s production of the non-vented lock screws.

All inquiries regarding this research project must be by email.

To contact me..... This email address is being protected from spambots. You need JavaScript enabled to view it.">CLICK HERE