M14 Test and Prototype Magazines ©

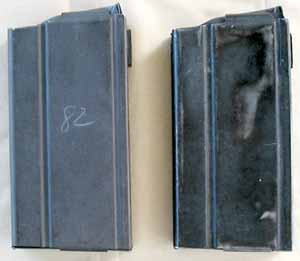

Circa 1961/62 a test was conducted to mass produce cheaper, expendable magazines. The test consisted of one aluminum and two different plastic designs. The aluminum version is illustrated here on the left side of the image. The magazine is approximately 1/2 the weight of the standard Borg Warner magazine on the right. The seam on the aluminum magazine has the same 13 welds, but as we will see further down there is one major difference.

To accommodate the available lighting, I was required to reverse the magazines' positions for this photo. The aluminum magazine is on the right. The aluminum mag's seam, which is reversed from the standard, is barely visible. Note the standard steel magazine on the left has the seam on the right of the magazine's front. The aluminum was bent and formed in the opposite direction, resulting in the seam being on the left side of the magazine's front. Both versions have 13* welds.

After testing, the remaining aluminum magazines were included in standard issue. I have seen a few packed in depot repacks over the years. A dealer with a large quantity of US GI magazines may find one or two within his lot. I have owned three and have seen a few more so keep your eyes opened, they are around if you look hard enough.

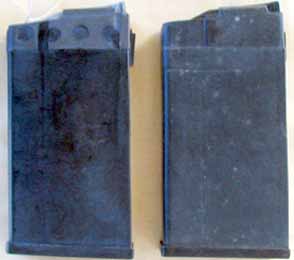

The two plastics are shown side by side. The one on the left is known as the "steel top". The upper portion has a steel liner which surrounds the outside of the plastic body. The steel top magazine was problematic for feeding. The other magazine is known as the "all plastic" magazine. The followers and floor plates of both magazines are plastic. Both had a molded plastic magazine lock, but the steel top's lock was mounted on a steel base, which was part of the liner. After testing the bulk of remaining plastic magazines were destroyed.

Front view of the two plastic magazines. The left has a good view of the steel liner. The liner was wrapped around the plastic body and had one single weld on the right of the magazine's front. Both magazines had well formed squared holes for locking the operating rod spring guide. I imagine wear would eventually become a problem with the all plastic magazine, but not with the steel top. The front body seam on the steel top was barely visible and it appears it was cleaned up and possibly polished for appearance. The front body seam on the all plastic was very visible.

On the left is the steel top, on the right is the all plastic. This rear view shows the rear seams. At the top of the steel top's magazine locking block is visible the small steel base which is part of the steel liner. The lock appears to be separating from the steel base, which was probably one of the design faults. This is the only known steel top magazine to survive due to the design problems of using the steel liner.

The steel top had a dull light gray follower. The all plastic had a shiny black follower. Due to advances in the plastics molding industry, these magazines look very crude when compared to modern production.

This is probably one of the very earliest prototype magazines, cut-away for demonstration. It has all the characteristics of normal production except for the magazine body. The "back plate" (for lack of a better term) of a production magazine is the same thickness as the rest of the body. This back plate is slightly thicker, giving the appearance of a separate piece of steel with a separation on each side. The ribs guiding the follower were done by a higher precision stamping process. This was probably early Springfield Production circa 1954/55.

The magazine has the standard 13* welds.

* Some people count the welds as 12. All US GI metallic magazines have 12 welds adjoining the seams but there is one more on the upper tab next to the locking hole for a total of 13.

|

Description |

Approximate Weights |

| Standard US GI Steel | 8.25 to 9.0 ounces |

| Aluminum | 4.25 ounces |

| Steel Top | 4.0 ounces |

| All Plastic | 3.75 ounces |

All inquiries regarding this research project must be by email.